Table of Contents

How Screw Feeding Systems Improve Efficiency in Manufacturing

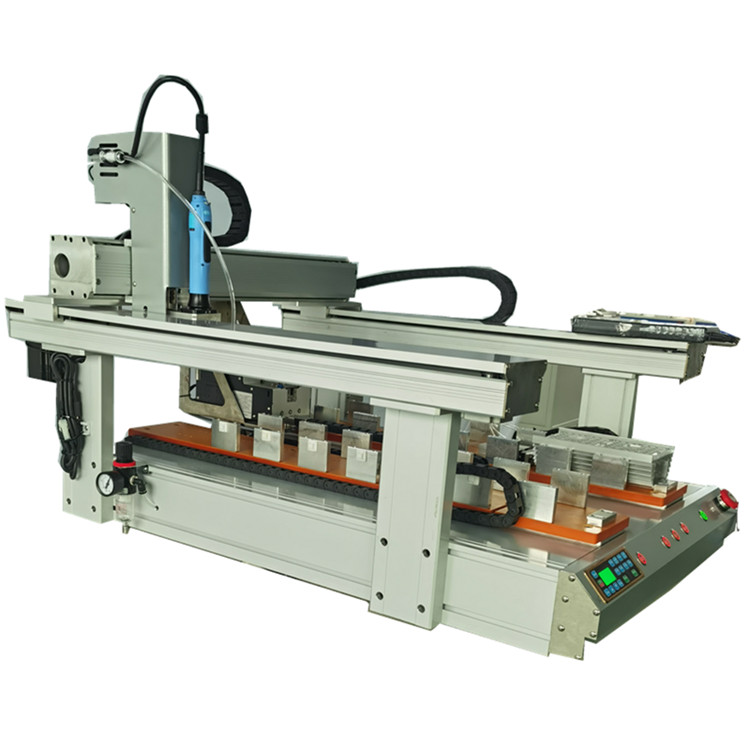

Manufacturing processes are becoming increasingly automated, and screw feeding systems are a key component of this automation. Screw feeding systems are designed to improve efficiency in manufacturing by providing a reliable, consistent, and automated way to feed screws into production lines. By automating the process of screw feeding, manufacturers can reduce labor costs, increase production speed, and improve product quality.

First, screw feeding systems reduce labor costs by eliminating the need for manual labor. Manual screw feeding is a time-consuming and labor-intensive process that requires a skilled operator to ensure that the screws are fed into the production line correctly. Automated screw feeding systems, on the other hand, can be programmed to feed screws into the production line with precision and accuracy. This eliminates the need for manual labor, which can significantly reduce labor costs.

Second, screw feeding systems can increase production speed. Manual screw feeding is a slow and tedious process that can significantly slow down production. Automated screw feeding systems, however, can feed screws into the production line quickly and accurately, allowing for faster production speeds. This can help manufacturers meet tight deadlines and increase their overall production output.

Finally, screw feeding systems can improve product quality. Manual screw feeding can lead to errors, which can result in defective products. Automated screw feeding systems, however, can feed screws into the production line with precision and accuracy, reducing the risk of errors and improving product quality.

In conclusion, screw feeding systems are an essential component of automated manufacturing processes. By automating the process of screw feeding, manufacturers can reduce labor costs, increase production speed, and improve product quality. As such, screw feeding systems are an invaluable tool for improving efficiency in manufacturing.

The Benefits of Automated Screw Feeding Systems for Assembly Lines

Automated screw feeding systems are becoming increasingly popular in assembly lines due to their numerous benefits. These systems are designed to streamline the assembly process, reduce labor costs, and improve product quality. Automated screw feeding systems can help companies increase their productivity and efficiency while reducing their costs.

One of the primary benefits of automated screw feeding systems is that they reduce labor costs. By automating the process of feeding screws into the assembly line, companies can reduce the number of workers needed to complete the task. This can result in significant cost savings, as fewer workers are needed to complete the same amount of work. Additionally, automated screw feeding systems can reduce the amount of time it takes to complete a task, as the system can feed screws into the assembly line quickly and accurately. This can help companies increase their productivity and efficiency.

Another benefit of automated screw feeding systems is that they can improve product quality. By automating the process of feeding screws into the assembly line, companies can ensure that the screws are fed into the assembly line in the correct orientation and with the correct amount of torque. This can help reduce the number of defective products that are produced, as the screws will be properly secured in the assembly line. Additionally, automated screw feeding systems can help reduce the amount of time it takes to complete a task, as the system can feed screws into the assembly line quickly and accurately.

Finally, automated screw feeding systems can help companies reduce their costs. By automating the process of feeding screws into the assembly line, companies can reduce the amount of time it takes to complete a task, as the system can feed screws into the assembly line quickly and accurately. This can help reduce the amount of time it takes to complete a task, as the system can feed screws into the assembly line quickly and accurately. Additionally, automated screw feeding systems can help reduce the amount of labor costs associated with the task, as fewer workers are needed to complete the same amount of work.

In conclusion, automated screw feeding systems offer numerous benefits to companies that use them in their assembly lines. These systems can help reduce labor costs, improve product quality, and reduce costs associated with the task. Automated screw feeding systems can help companies increase their productivity and efficiency while reducing their costs.